27 5.1: Temperature Danger Zone

5.1 Temperature Danger Zone

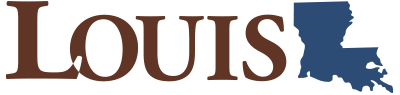

Time and temperature control of food helps keep pathogens from growing to unsafe levels. The temperatures at which pathogen growth happens the fastest are from 41°F–135°F / 5°C–57°C. This is known as the temperature danger zone. Pathogens grow even more rapidly when food is between 70ᐤF-125ᐤF/ 21ᐤC-52ᐤC. When food is kept above 135ᐤF (57ᐤC), pathogens die and can’t survive due to the heat. When food is kept below 41ᐤF (5ᐤC), the metabolic processes of pathogens slow to a halt due to the cold. This is why it is a mantra in the food industry “Hot food, hot and cold food, cold!”

The longer food spends in the temperature danger zone, the more pathogen growth it can experience. TCS foods can only spend a total of 4 hours in the temperature danger zone before they must be discarded. Because a food employee does not know what has happened to food before it shows up on the premises of their operation, it’s reasonable to assume that food has already spent some time in the danger zone. This makes it all the more important that food spends as little time in the danger zone as possible.

Time and Temperature Control Practices

Food has to be protected from the danger zone during storage, preparation, cooling, reheating and serving. The best way to do that is to carefully monitor food at every step along its journey through the operation. Management teams must have a system in place that allows food workers to check and recheck food for safety. The plan should include:

- A list of foods to be monitored with the frequency they should be checked

- Recorded documentation of the monitored foods

- Thermometers are in good working order

- The food worker or position responsible for logging temperatures

- A detailed list of corrective actions when food does not meet standards

Monitoring TCS foods

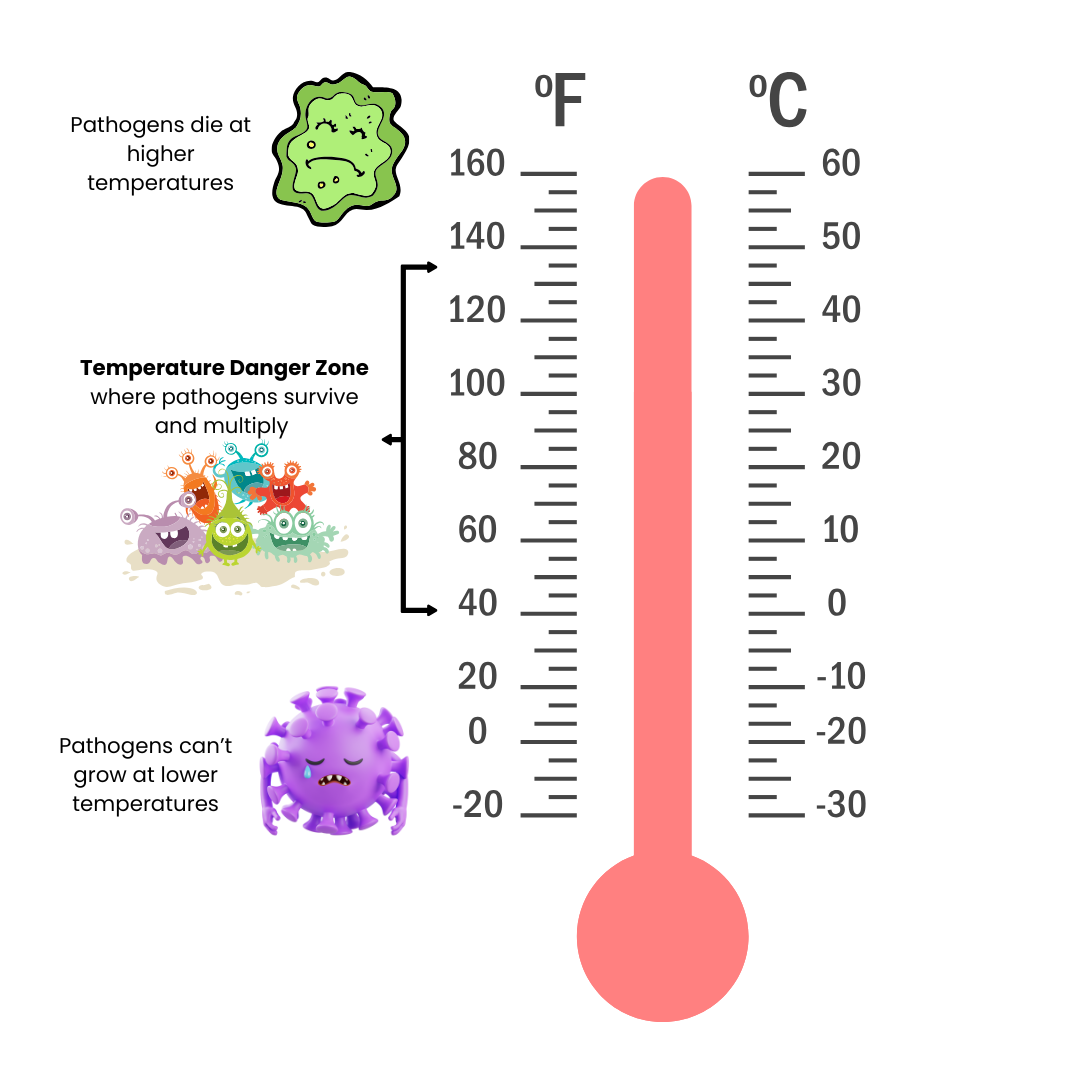

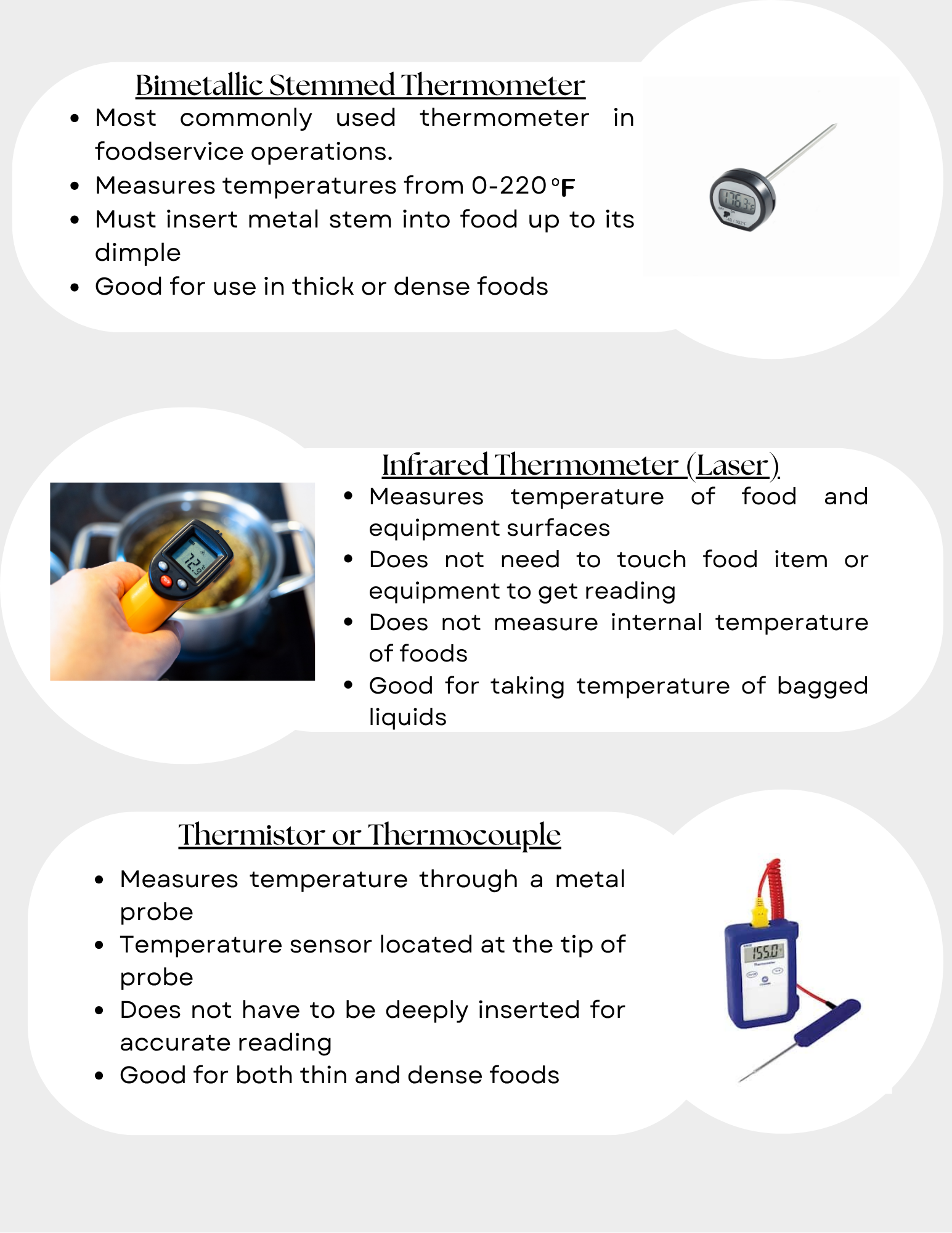

Controlling TCS food time in the danger zone is done through monitoring food temperature. The most commonly used tool for temperature monitoring is a thermometer. Various types of thermometers are used in foodservice operations. The chart below shows the types and their uses.

In the case of the thermistor and thermocouple thermometers, note that there are several different types of probes that can be used. Immersion probes are inserted into liquids to check temperature. Air probes help test the ambient air temperature inside of ovens and coolers. Surface probes check the temperature of equipment. Penetration probes can be inserted and can be used to check the internal temperature of thin food items like a single portion of protein since the sensor is located in the tip of the probe. For all thermometers it is best to ensure that there are no barriers to the food item in order to get a proper reading. Temperatures should not be taken through equipment, storage containers or food packaging.