70 11.3: The Physical Facility

Whether undergoing new construction or a remodel, the layout, construction materials, and equipment must be carefully considered. Consulting with the local regulatory authorities during the initial planning phase will save time and money in the long run. Everything from the floor to the ceiling to the exterior needs to be carefully planned for safety, durability, cost, and functionality. Adequate equipment must be available to maintain a safe environment and reduce hazards. Preventative and regular maintenance should be performed to prevent equipment from failing, resulting in hazardous conditions.

Floors

Flooring used in food preparation, storage, and warewashing areas should be durable, slip-resistant, easy to clean, and nonabsorbent. Flooring materials should prevent the growth of microorganisms, harborage of rodents, and pooling of moisture. Carpet is not allowed in food preparation areas, warewashing areas, or toilet rooms. Floor mats can help reduce employee fatigue and slipping.

Coving, commonly referred to as baseboards or floor molding, seals the wall to the floor. Coving prevents pests from accessing the space between the walls. Coving also prevents mop water and other liquids from reaching between the walls, which could result in mold and mildew growth. It is best to have coving that is rounded (or curved) where it connects the wall to the floor, versus a sharp 90° angle. This will allow dirt to be easily removed when mopping/sweeping and not become trapped.

Walls & Ceilings

Walls and ceilings are to be smooth, easily cleanable, non-absorbent, and light-colored. Wood studs, joists, and ceiling rafters shall not be exposed in food preparation, storage, and warewashing areas.

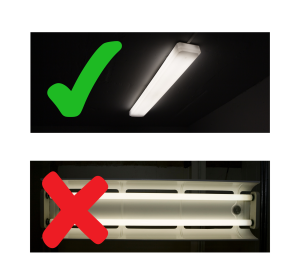

Lighting

Sufficient lighting levels are required for employees to perform satisfactory functions. Employees must be able to read labels, visually identify hazardous situations, and evaluate the appearance of food and equipment. Lighting intensity should be high in food prep and warewashing areas. Light bulbs should be shatter-resistant or shielded to prevent glass from contaminating food preparation, storage, and warewashing areas.

Movable vs. Fixed in Place Equipment

When selecting equipment, the mobility of the equipment should be evaluated. Equipment that has water or gas lines or is too large to move is considered immobile or fixed. Fixed equipment must have sufficient clearance under, above, and on the sides of the equipment to clean properly.

Floor-mounted fixed equipment should be elevated at least 15 centimeters (6 inches) above the floor. Counter-mounted fixed equipment should be elevated at least 7.5 centimeters (3 inches) above the counter surface. The alternative would be to place the equipment no more than 1 millimeter from the wall, ceiling, or adjoining equipment or to permanently seal it to the floor, ceiling, or adjoining equipment with no gaps. Easily movable equipment can be lifted, pushed, or moved from the equipment’s normal location to clean under, above, and behind.

Clean in Place Equipment

A piece of equipment designed for cleaning in place (CIP) must have access points to monitor the cleaning and sanitizing solutions that are circulated throughout the system. The CIP

equipment is designed to be cleaned and sanitized without disassembling. A few examples of CIP equipment include:

- Beverage Dispensers

- Coffee Machines

- Food Storage Tanks

- Food Processing Equipment (mixers, blenders)

- Dishwashers

- Homogenizers

Food Temperature Measuring Devices

There are numerous options to consider when selecting food temperature measuring devices. The most cost-effective is the analog dial pocket thermometer.

- The dial should have a range from 0°F (-18°C) to 220°F (104°C), which allows for measuring cold and hot foods.

- Each time the thermometer is used, the stem must be cleaned and sanitized. Pocket thermometers have a storage sheath that protects the stem when not in use.

- The thermometer should be calibrated before the initial use, when dropped, exposed to extreme temperatures, or at the beginning of each shift.

- The entire sensing area of the stem should be inserted into the food when measuring the temperature.

Digital temperature measuring devices are another option to consider when selecting a thermometer. There are multiple types and should be selected accordingly. The advantage of a digital temperature measuring device, unlike the analog pocket thermometer, is that only the tip needs to be inserted into the food to get an accurate reading. After each use, the thermometer probe must be cleaned and sanitized.

Infrared temperature measuring devices are a suitable option to measure the surface temperature of equipment. Infrared thermometers are not capable of measuring internal food temperatures and should therefore not be used for this purpose.

Food and ambient (air) temperature measuring devices should be easy to read and accessible. Avoid using temperature measuring devices that contain glass or are mercury-filled, as this can present physical or chemical hazards. All refrigeration units, refrigerators, or freezers that contain time-temperature-controlled for safety (TCS) foods, must have a permanent temperature measuring device. The temperature measuring device used to measure the ambient temperature of a refrigerator or freezer must be accurate to ± 2.7°F (1.5°C) and located in the warmest area of the unit.

Hot and Cold Holding Equipment

Hot holding equipment should be capable of maintaining acceptable temperatures of hot foods, minimum of 135°F (57°C). Hot holding equipment is not capable of reheating food items, only maintaining the temperature of hot foods. Cold holding equipment should be capable of maintaining acceptable temperatures for cold foods, maximum of 41°F (5°C) .

Cooking and Baking Equipment

Cooking and baking equipment must be cleaned regularly to prevent the buildup of food and grease on food and non-food surfaces. Accumulation of food on equipment can result in attracting rodents and insects. Buildup of grease on equipment can result in a fire hazard.

Refrigeration

Foodservice operations are required to have sufficient refrigeration to keep foods at the proper temperature. When purchasing refrigerators and freezers, managers should consider construction material, utility needs, design, space, mobility, and capacity. Shelving in the units should allow for unrestricted air flow. Door seals should be in working order, cleaned regularly, and replaced when they are no longer functioning properly. Temperature measuring devices should be located inside the unit in the warmest area. The internal fan and behind the unit should be free of dust, and the space between the unit and the wall should be sufficient to allow air to circulate.

Commercial single rack warewashing machine

Warewashing Machines

The visible data plate of the warewashing machine includes the required operating specifications of the:

- temperature required for washing, rinsing, and sanitizing

- pressure required for the sanitizing rinse

- conveyor speed for conveyor machines or cycle time for stationary rack machines

All warewashing machines should automatically dispense detergent, and chemical sanitizing machines should automatically dispense sanitizer. An indicator or alarm installed on the machine will alert users when chemicals are not dispensing correctly. Warewashing machines and sinks need to be cleaned:

- Before use

- Throughout the day, as needed

- If used, at least every 24 hours

A temperature measuring device is required to measure the minimum temperature of cycles for both chemical and heat sanitizing machines. Effective sanitation in a heat sanitizing warewashing machine occurs when the surface temperature of utensils reaches a minimum of 160°F (71°C). The wash solution temperature of a heat sanitizer machine may not be less than:

- 165°F (74°C) for a stationary rack, single temperature machine

- 160°F (71°C) single tank, conveyor, dual temperature machine

- 150°F (66°C) for a stationary rack, dual temperature machine; multitank, conveyor, multi-temperature machine

The wash solution temperature for chemical sanitizing machines should be at least 120°F (49°C).

The water used to sanitize in a heat sanitizing machine must be between 194°F (90°C) and:

- 165°F (74°C) for a stationary single rack machine

- 180°F (82°C) for all other machines

A flow pressure device will indicate the final sanitizing rinse pressure of a heat sanitizing machine. The water flow pressure should be calibrated to meet the specifications on the manufacturer’s data plate.

Manual Warewashing Sink

The sink compartments should be large enough to efficiently and effectively clean and sanitize large equipment and utensils. Alternative equipment must be available if the equipment cannot be effectively cleaned in the warewashing sink. Approved detergents used to clean equipment and utensils should be provided. The first sink compartment containing the detergent should maintain water at a temperature of not less than 110°F (43°C). A drainboard for air drying items must be self-draining and not pool water. Handwashing is not allowed in a warewashing sink. Before use, each sink compartment should be cleaned and sanitized.

The third compartment of a three-compartment sink is where sanitizing takes place. The two options are chemical or heat sanitization. If heat is the method of sanitizing, the water in the sanitizing compartment must maintain a temperature of 171°F (77°C). A readily accessible water temperature measuring device and a basket to lower and raise equipment safely into the hot water are required. If using a chemical sanitizer to sanitize equipment and utensils, a test kit must be readily available for measuring concentration in mg/L of the sanitizer.

Handwashing Sink

Handwashing stations should be located in (or by) the food prep areas, warewashing areas, service areas, and restrooms. The station must contain a sink, soap, a means to dry hands, a trash receptacle, and proper signage. The only task completed in this sink is handwashing.

The water temperature in the handwashing sink must reach a minimum temperature of 100°F to effectively loosen and remove any physical particles from the hands. The soap must be capable of lathering to loosen any physical, chemical, or biological hazards from the hands. The soap can be a bar, powder, foam, or liquid, and does not have to be antimicrobial. The purpose of soap is to lubricate and remove any and all hazards from the hands, not necessarily kill microorganisms. Using an antimicro

Handwashing Signage

bial soap provides additional protection. Two acceptable methods for drying hands are using a single-use paper towel or an air dryer. It is not necessary to have both methods at the sink. The PIC should ensure that food employees are not using kitchen towels or aprons to dry hands. A trash receptacle with a lid is also required. This provides a designated area for disposing of used gloves and paper towels. Lastly, signage posted reminding employees they are required to wash their hands frequently throughout the day.

Service Sink

A service sink should be made available to rinse mops, brooms, dustpans and other cleaning equipment. Food prep or hand washing should not take place in this sink.

Ice Machines/ Ice Storage Containers/Buckets/Chests

An ice storage bucket

Drain lines for ice machines and storage containers have a high potential for mold and mildew growth. Attention must be taken to clean and sanitize regularly to prevent this hazardous condition. The inside storage compartment of ice machines/buckets/chests should be cleaned, sanitized and descaled. Descaling removes the mineral buildup from hard water. The ice scooper must be stored outside the ice or have a handle guard to prevent cross contamination. Ice storage buckets should only be used for ice transportation.

Vending Machines

Vending machines should be designed to prohibit rodents from entering. Vending machines that contain foods needing temperature control should be closely monitored and only vend foods that have been stored safely. The vending machine should include an automatic shut off when the food reaches unsafe temperatures.

Shellfish tank

Molluscan Shellfish Tanks

Because of the nature of an onsite shellfish display tank, high concentrations of pathogens increase the risk of bacteria and virus contamination. Regulatory approval and a detailed HACCP plan must be in place if shellfish from a tank onsite are served.

the structure and interior surfaces of a food establishment including accessories such as soap and towel dispensers and attachments such as light fixtures and heating or air conditioning system vents.

equipment that is not portable and is designed to be mounted off the floor on a table, counter, or shelf.

Portable; mounted on casters, gliders, or rollers; or provided with a mechanical means to safely tilt a unit of EQUIPMENT for cleaning; and having no utility connection, a utility connection that disconnects quickly, or a flexible utility connection line of sufficient length to allow equipment to be moved for cleaning of the equipment and adjacent area.

a lavatory, a basin or vessel for washing, a wash basin, or a plumbing fixture especially placed for use in personal hygiene and designed for the washing of the hands.

to remove the mineral buildup from hard water