32 6.2: Receiving Deliveries

Receiving deliveries is an important step in the flow of food through the establishment. If care is not taken during the inspection process, it can be costly. Not only financial consequences, but the health and safety of the consumer is at risk. Sufficient staff, tools, and time must be allocated to the receiving process and standard operating procedures should be followed.

Large facilities may have a full time purchasing and receiving manager whose main responsibility is ensuring the food procurement process is completed properly. Smaller facilities will assign this task to an employee whose main responsibility is elsewhere. Either situation can lead to deficiencies if standard operating procedures are not followed.

Depending on the size and number of deliveries, sufficient staff should be available to review the delivery then store in the appropriate area immediately after receiving.

Deliveries should take place during off peak hours. An agreement between the food service facility and the food/supply distributor should outline allowable time slots for deliveries that do not disrupt the normal operations of the business. Typically there are designated days that deliveries will be provided.

The receiving area should be clean and free of clutter. This will allow the receiving process to flow efficiently and prevent rodents and insects from entering the facility. Exterior doors and bays should be kept closed when not receiving deliveries to prevent insects and rodents from entering.

The receiving area should be clean and free of clutter. This will allow the receiving process to flow efficiently and prevent rodents and insects from entering the facility. Exterior doors and bays should be kept closed when not receiving deliveries to prevent insects and rodents from entering.

A visual inspection of the delivery vehicle should be made. Refrigerated and frozen foods should be held in a temperature controlled environment during the delivery process. The truck compartment should be free of trash, rodents, insects or insect parts.

The designated receiving employee  should have the purchase order (P.O.) to compare to the invoice and the actual items received. The P.O. will specify the items, brands, form, pack size, quantities, and prices. Any discrepancies should be noted. The invoice should reflect the items being delivered. The brands, quantities, form, pack size should be compared to the items delivered and discrepancies noted.

should have the purchase order (P.O.) to compare to the invoice and the actual items received. The P.O. will specify the items, brands, form, pack size, quantities, and prices. Any discrepancies should be noted. The invoice should reflect the items being delivered. The brands, quantities, form, pack size should be compared to the items delivered and discrepancies noted.

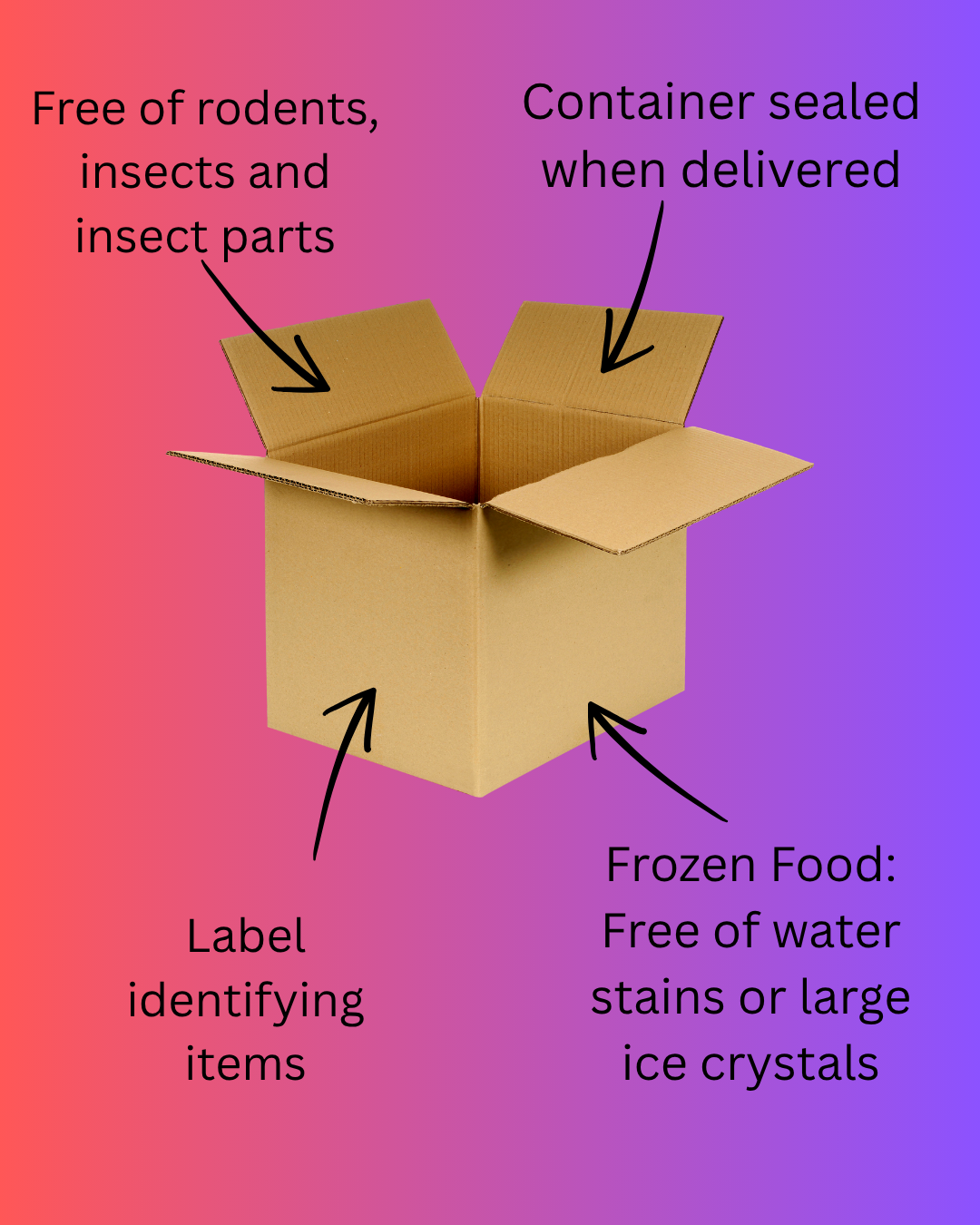

A visual inspection of the delivered items should take place first. Any items that do not meet purchasing standards should be rejected. A few key visual characteristics that would require rejection of an item are:

-

-

-

- Spoiled

- Expired

- Adulterated

- Label missing

- Molded

- Off Odor

- Damaged

- Opened

- Rusted, Swollen, Dented Cans

- Leaking Vacuum Sealed Items

- Water stained boxes

- Temperature abused items, i.e. frozen items defrosted

- Large ice crystals on frozen foods

- Boxes with insects, insect parts, or rodent droppings

-

-

- Thermometers and scales should be readily available in the receiving area.

- Internal temperature of refrigerated and frozen items needs to be taken before accepting a delivery. If the items do not meet temperature guidelines, those items should be rejected. A scale should be used for items that should be weighed.

- As soon as the receiving process is complete, all items should be stored properly. Dollys and carts can be used to transport food and supplies from the receiving area to the storage area. Proper lifting techniques should be followed. See chapter 7 for Storage guidelines. Food and supplies should not be stored on the floor during the receiving process. Temporarily storing boxes on pallets is acceptable as long as the items are six (6) inches off the floor.